Backflow testing is a crucial process that ensures the safety of your water supply by preventing contaminated water from flowing back into the system. In this handy guide, you’ll find all the essential information you need to understand the importance of backflow testing and how it works.

Learn about the various types of backflow devices, the testing procedure, common issues, and why regular testing is necessary to protect your health and the environment. So, let’s dive in and explore the world of backflow testing together!

What Is Backflow Testing?

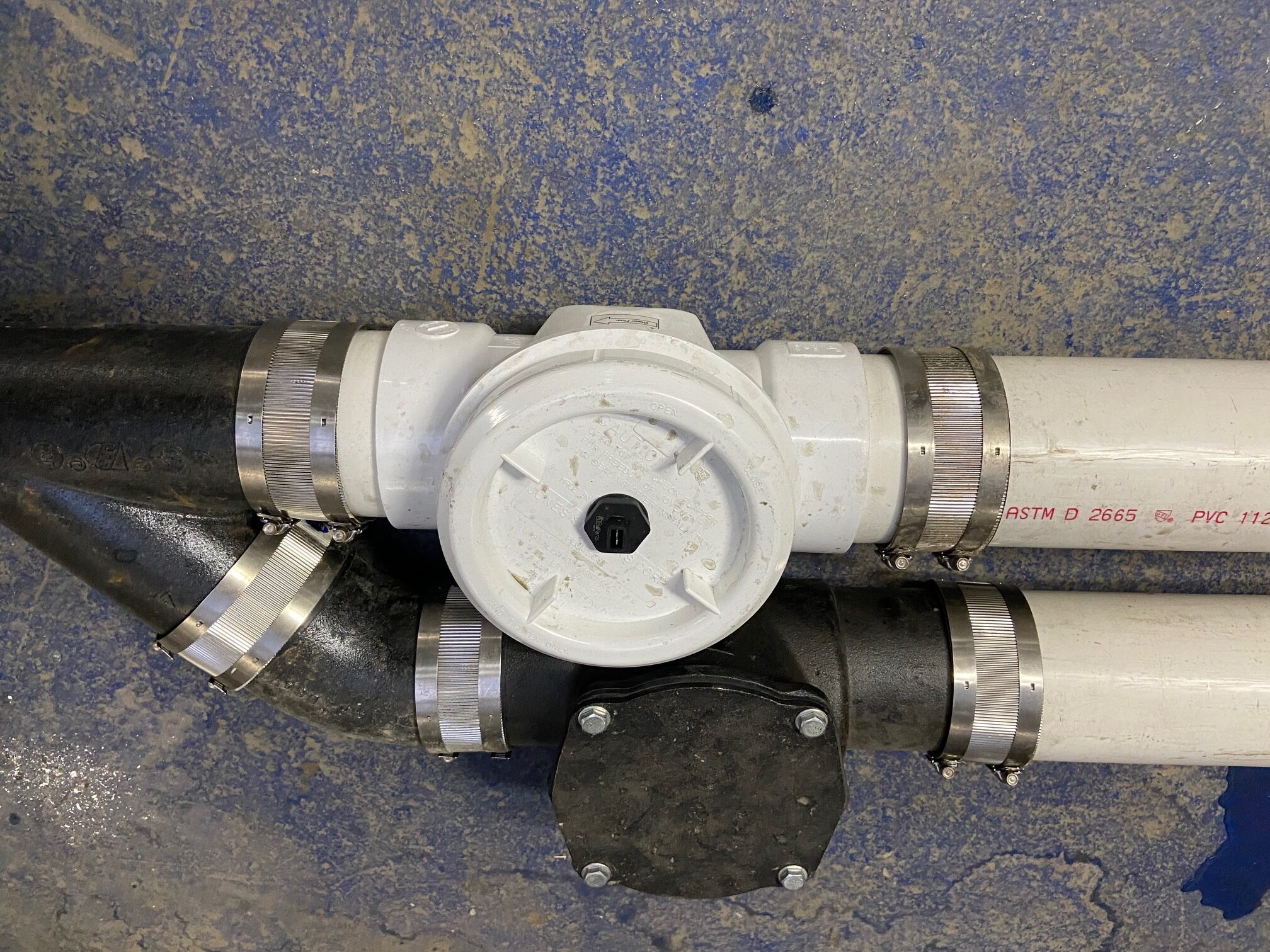

Backflow testing is a crucial process that ensures the safety of our drinking water. By checking for any reverse flow of contaminated water into the clean supply, this handy guide helps you understand the importance of backflow testing in maintaining water quality.

Credit: www.balkanplumbing.com

Importance Of Backflow Testing

Understanding the importance of backflow testing is crucial for ensuring the safety and quality of our drinking water. Let’s explore why backflow testing is essential for protecting public health and complying with regulations.

Protecting Drinking Water

Backflow testing plays a key role in safeguarding our drinking water from contamination. By detecting and preventing backflow incidents, we can maintain the purity of our water supply and prevent the spread of harmful pollutants.

Legal Compliance And Regulations

Backflow testing is not just about protecting drinking water; it is also a legal requirement mandated by various regulations. Ensuring that backflow prevention devices are tested regularly helps properties comply with local and national laws to maintain public health standards.

When And How Often To Conduct Backflow Testing

Backflow testing should be conducted annually to ensure the safety of the water supply. It is important to schedule testing at least once a year to prevent any potential contamination. The frequency of testing may vary depending on the local regulations and the type of backflow prevention devices in place.

Understanding when and how often to conduct backflow testing is critical for maintaining the safety and purity of your water supply. It is essential to adhere to the recommended testing frequency and to consider various factors that can affect the timing of testing to ensure the continued protection of your water system.Frequency Of Testing

When it comes to backflow testing, the frequency at which it should be performed is determined by federal, state, and local regulations. Generally, backflow preventer devices should be tested at least once a year. However, certain factors might necessitate more frequent testing to mitigate potential risks.Factors Affecting The Timing Of Testing

Regular Maintenance Schedule: Backflow preventers located in areas with high contamination risks, such as chemical plants or irrigation systems, may require testing more frequently. Additionally, recent repairs or replacements of the backflow prevention assembly may warrant immediate testing to ensure its effectiveness. Water Contamination Risks: If your water system is at risk of contamination due to nearby construction, floods, or other environmental changes, it is crucial to conduct more frequent backflow testing to safeguard the purity of your water. Federal, State, and Local Regulations: Regulations vary by location, and it is essential to adhere to the specific requirements of your municipality. Some areas may have stricter regulations that necessitate more frequent backflow testing to comply with local ordinances. By understanding the frequency and factors influencing backflow testing, you can ensure the ongoing protection of your water system and mitigate potential risks of contamination. Regular and timely testing is crucial in preserving the safety and quality of the water supply, ultimately safeguarding the health and well-being of the community.

Credit: backflowdirect.com

The Backflow Testing Process

Understanding the backflow testing process is crucial for maintaining the safety and quality of your water supply. Backflow occurs when contaminated water flows backward into the clean water supply. To prevent this from happening, regular backflow testing is essential. In this handy guide, we will take you through the step-by-step process of backflow testing, ensuring the safety and integrity of your water system.

Initial Inspection

Before conducting any backflow testing, a thorough initial inspection is necessary to assess the condition of your water system. A certified backflow tester will examine your plumbing connections, backflow prevention devices, and any potential hazards that could contaminate the water supply.

The initial inspection involves:

- Identifying all backflow prevention devices in your system

- Checking for physical damage or signs of wear and tear

- Evaluating the condition and proper functioning of existing backflow prevention devices

- Determining any potential cross-connections

Based on the findings of the initial inspection, the tester will develop a plan for the backflow testing process, ensuring that all safety measures are in place to protect your drinking water.

Testing And Maintenance Procedures

Once the initial inspection is complete, the backflow testing and maintenance procedures can be carried out. This involves the following steps:

- Shutting off the main water supply: The water supply to your property needs to be isolated to prevent any interference during the testing process.

- Testing the backflow prevention devices: The certified tester will evaluate the performance of each backflow prevention device in your system. This involves following specific testing procedures to measure the device’s ability to prevent backflow effectively.

- Performing necessary repairs or replacements: If any backflow prevention devices are found to be faulty or not meeting the required standards, the tester will make the necessary repairs or recommend replacements. This ensures that your water system remains protected against potential contamination.

- Re-testing and certification: After any necessary repairs or replacements, the backflow prevention devices will be re-tested to ensure their proper functioning. Once deemed satisfactory, a certification will be issued, stating that your water system meets the required standards of backflow prevention.

- Ongoing maintenance: Regular maintenance of the backflow prevention devices is vital to ensure their continued effectiveness. The certified tester may provide recommendations for future maintenance and testing schedules, enabling you to stay compliant and safeguard your water supply.

By following the backflow testing and maintenance procedures, you can mitigate the risk of backflow and ensure the safety of your drinking water. It is essential to engage a certified backflow tester for these tasks to guarantee accurate assessments and proper implementation of preventative measures.

Qualifications And Certification For Backflow Testers

Understanding the qualifications and certification for backflow testers is crucial for ensuring the safety and efficiency of our water supply systems. Qualified and certified professionals play a vital role in preventing the contamination of potable water. Proper training, education, and certification are essential aspects to look for when selecting a backflow tester.

Training And Education Requirements

Backflow testers are required to undergo comprehensive training and education to develop the necessary skills and knowledge to perform their responsibilities effectively. The training should cover topics such as hydraulic principles, backflow prevention devices, testing procedures, and relevant regulations.

Certification Process

The certification process for backflow testers involves fulfilling specific requirements and passing an examination to demonstrate proficiency in backflow testing. Certified testers are equipped with the latest industry knowledge and are well-versed in the proper maintenance and testing of backflow prevention devices, ensuring the safety and quality of our water supply.

Common Issues And Failures In Backflow Testing

Discovering common issues and failures in backflow testing is crucial for maintaining water safety. Identifying leaks and valve problems ensures compliance and protects the potable water system. Regular testing helps prevent contamination risks and safeguards public health.

When it comes to backflow testing, there are several common issues and failures that can occur. It’s important to be aware of these problems to ensure the safety and efficiency of your plumbing system. In this section, we will explore the causes of backflow failure and how to address and resolve these failures.

Causes Of Backflow Failure

Backflow failure can be caused by various factors, including:

- Malfunctioning Check Valves: Check valves are essential in preventing backflow, but when they malfunction or become worn out, they can allow water to flow in the wrong direction.

- High Water Pressure: Excessive water pressure in the plumbing system can cause backflow failure by overpowering the check valves and forcing water to flow backward.

- Improper Installation: If backflow prevention devices are not installed correctly or if they are the wrong size for the plumbing system, backflow failure is more likely to occur.

- Backflow Preventer Maintenance: Neglecting regular maintenance on backflow preventers can lead to failure. It’s essential to have them inspected and serviced regularly by a qualified professional.

Addressing And Resolving Failures

If a backflow failure is detected during testing, prompt action is required to address and resolve the issue. Here are some steps to take:

- Identify the Cause: Determine what caused the backflow failure by inspecting the check valves, water pressure, and overall system installation.

- Repair or Replace Faulty Components: If malfunctioning check valves are identified, they should be repaired or replaced as soon as possible. Additionally, if high water pressure is the cause, a pressure regulator may need to be installed to prevent future failures.

- Perform Regular Maintenance: To avoid future failures, it’s crucial to establish a maintenance schedule for backflow preventers. This includes regular inspections, cleaning, and any necessary repairs.

- Retest the System: Once the necessary repairs or replacements have been made, the system should be retested to ensure that the backflow issue has been resolved.

By addressing and resolving backflow failures promptly, you can maintain a safe and efficient plumbing system. Regular testing and proper maintenance are key to preventing issues in the future. If you are unsure how to perform backflow testing or need assistance with resolving failures, it’s recommended to consult a professional plumber with expertise in backflow prevention.

Cost Considerations For Backflow Testing

Understanding backflow testing is crucial to safeguarding the quality of your water supply. A key aspect to consider is the cost implications associated with this essential maintenance procedure.

Potential Expenses

The cost of backflow testing can vary based on several factors, from the size of your property to the complexity of your plumbing system.

Factors Influencing Costs

- Type of backflow prevention device installed

- Number of devices requiring testing

- Accessibility of the devices

- Location of the backflow prevention assemblies

- Local regulations and certification requirements

Credit: www.amazon.com

Choosing A Backflow Testing Service Provider

As you delve into the world of backflow testing, an essential aspect is Choosing a Backflow Testing Service Provider. This decision can impact the safety and efficiency of your water systems. Let’s explore what qualities to look for and questions to ask potential providers:

Qualities To Look For:

- Experience in backflow testing and certification

- Knowledge of local regulations and compliance requirements

- Prompt and reliable service

- Proven track record of customer satisfaction

Questions To Ask Potential Providers:

- What certifications do your technicians hold?

- How do you stay updated on changing regulations?

- Can you provide references from satisfied clients?

- What is your typical turnaround time for testing and reports?

Frequently Asked Questions

What Is Backflow Testing?

Backflow testing is the process of evaluating and ensuring the proper functioning of a backflow prevention device. It helps to prevent the reverse flow of contaminated water and protects the water supply from contamination.

Why Is Backflow Testing Important?

Backflow testing is crucial because it ensures the safety and quality of our drinking water. By detecting and fixing any issues with backflow prevention devices, it prevents the contamination of water sources and keeps our water supply safe for consumption.

How Often Should Backflow Testing Be Done?

Backflow testing should be performed annually to comply with local regulations and ensure the continuous protection of the water supply. Regular testing helps to identify any issues promptly and allows for timely maintenance and repairs to prevent potential backflow incidents.

Conclusion

Backflow testing is essential for maintaining a safe and healthy water supply. By understanding the process and its importance, you can ensure the protection of your community and environment. Regular testing and maintenance are crucial to prevent potential contamination and health risks.

Stay proactive and keep your water system secure.